Kaizen Business Consulting: The Principle of Continuous Improvement

29 Sep, 2020 | By leslie@leanexpansion.ca

The idea of performance improvement has been around for more than one hundred years. Rooted in the manufacturing process, it has evolved to meet the needs of modern business processes.

Kaizen is a Japanese term meaning to “change for the better” or “continuous improvement.” It is a methodical process of consistently and gradually improving operations. Success hinges on involving those closest to the work to make change.

As a business consultant in Toronto, I work with clients across North America and typically see the term kaizen being used in three ways.

Kaizen Business Consulting – The Rapid Improvement System

Kaizen blitz is the first and most common use of the term, sometimes also referred to as a rapid improvement event. It’s a dedicated time when a team comes together, over several sequential days. A problem is presented to the team. Under the guidance of a facilitator, team members study the problem and present solutions. The drawback I see as a business consultant is that too often, no one really studies the problem. The default is that everyone surmises what’s happening. There is no testing or changes, which, to me, isn’t the true spirit of kaizen.

Kaizen Business Consulting – The Continuous Improvement System

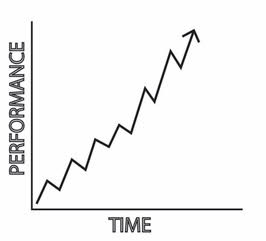

Occasionally, I meet an organization that has embraced the idea of consistent improvement and made it part of their culture. By continually introducing small, positive changes, an organization can establish an upward trajectory that’s simply unmatched by competitors.

As the business world shifts from a predominantly analog world to digital, this concept of kaizen is taking off. Historically, clients that have embraced kaizen as a practice, have easily outpaced customer expectations and achieved double-digit results in terms of improvement. We accomplished this with a handful of improvement cycles per week, following a simple pattern: Change – Measure – Learn – Repeat.

Technical advances have changed how kaizen is managed in organizations today, particularly if you’re looking at the tech sector. Modern organizations vying to outpace competitors deploy code changes hundreds, even thousands of times per day. And every time, measurement and learning takes place before the next update is released.

Kaizen Business Consulting – The Belief System

My favourite use of the term kaizen is less an action than a total belief system. The idea is everything is improvable. The more insight you have around your customers, products, and processes, the greater the opportunities to make changes for improvement. Breakthrough and positive disruption is always possible. There is no debate around if something can be improved—only how it can be improved.

Kaizen Business Consulting in Toronto

As a senior business consultant in Toronto, I work with companies across North America. As a kaizen specialist, my goal is setting up scalable solutions to improve processes around manufacturing, logistics, customer service, and much more. See kaizen in action by reading my Healthcare study. Interested to learn how kaizen can improve operations in any industry? Ask me a question.