Before our work, all improvement was thought of in seasons. What can we do to make next season better?

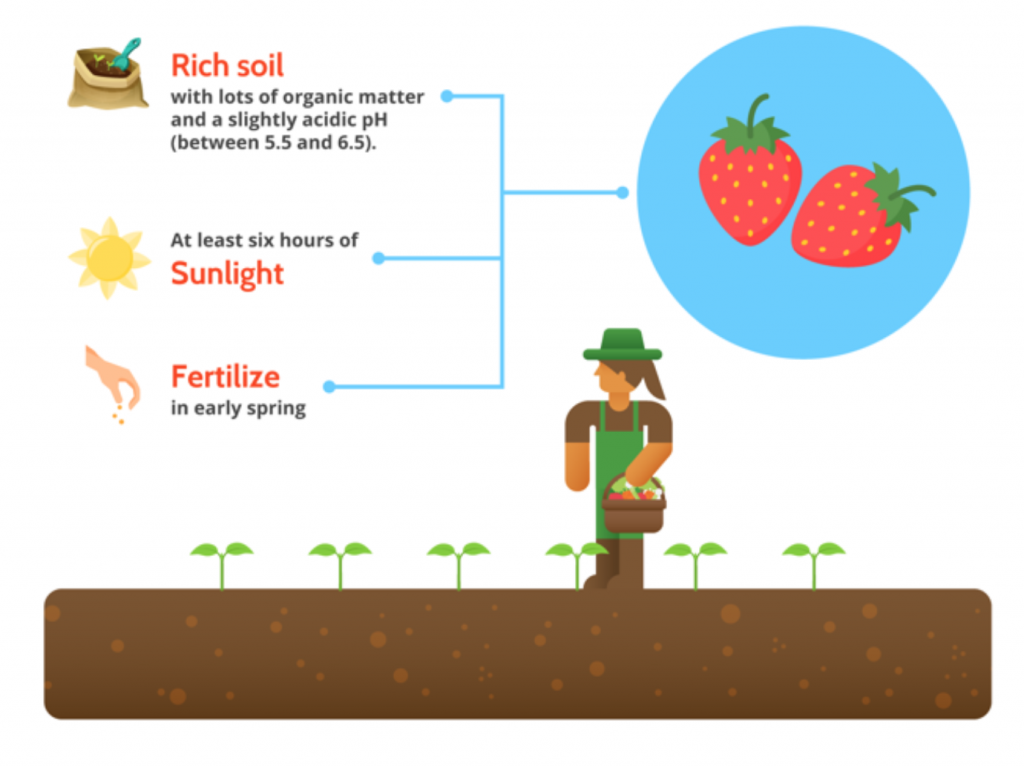

If I could reinvent myself, I think it would be as a farmer. I truly enjoyed spending my days in sunny fields, learning to work the soil to grow the most delightful berries on earth. The problem my client faced: they were growing. How can they fulfill high rates of demand and continue to delight customers?

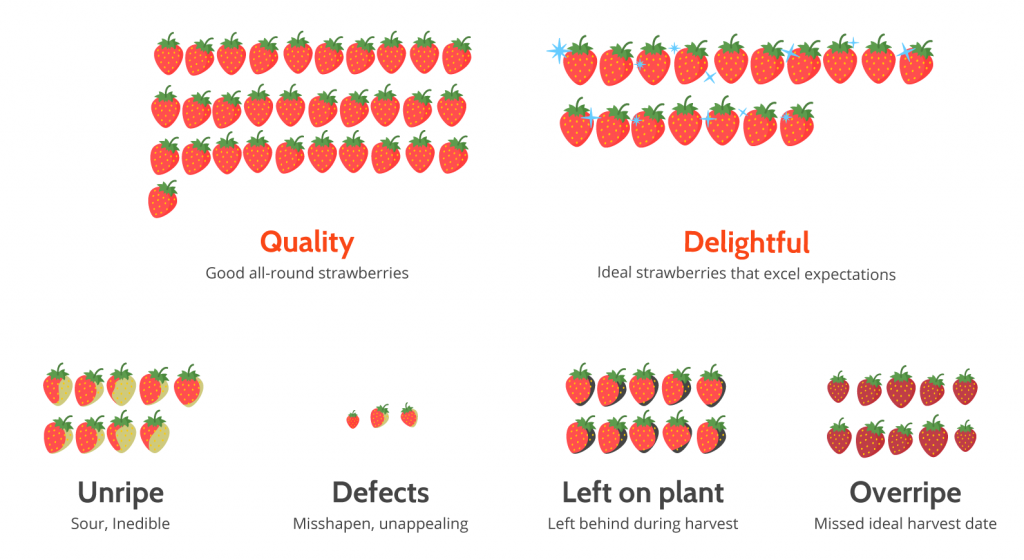

We visited grocery stores where their product was sold. We tapped into reams of customer survey data to understand the voice of the customer. Categorizing their defects was the first task. Wrong shape. Inconsistent color. Poor taste. Over-ripe.

We mapped the process to understand where defects were being introduced, following the results of our investigation. We set up experiments in different fields to gain insight. This was huge. Prior to our work all improvement was thought of in seasons. What can we do to improve next season? The trouble is that change is a year away.

Figure 1. High Level Value Stream Map for Strawberries

Inspired by today’s start-ups, we drew on the idea of increasing the cycles of learning. What can we do immediately that will help today? Next week? Next month? Better guides for the harvesters. Reduce time to distribution. Many ideas flowed, experiments established, and delight grew. This product line saw profits they hadn’t seen in over ten years.

Figure 2. Physical Mapping of Defects